Investment Casting Equipment: A Comprehensive Overview

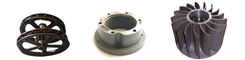

Investment casting, also known as lost wax casting, is a precise and versatile manufacturing process used to create complex and intricate metal components. It requires specialized equipment to achieve accurate and high-quality results. In this article, we will provide a comprehensive overview of investment casting equipment, including its key components, the casting process, and the benefits it offers.

Overview of Investment Casting:

Investment casting is a metal casting process that dates back thousands of years. It involves creating a wax pattern or replica of the desired part, coating it with a ceramic shell, and then melting the wax out to leave a hollow mold. Molten metal is then poured into the mold, filling the cavity, and solidifying to form the final component. The ceramic shell is broken away, and the finished part is cleaned and finished to the desired specifications.

Investment Casting Equipment:

- Wax Injection Equipment: The wax injection process is the first step in investment casting. Wax injection equipment is used to create wax patterns or replicas of the desired parts. It typically consists of a wax injector machine, which forces molten wax into a precision-made metal die to produce the wax patterns. The equipment ensures precise control over the injection process, including temperature, pressure, and injection speed, to create accurate and high-quality wax patterns.

- Shell Building Equipment: Once the wax patterns are created, they are coated with a ceramic shell to form the mold. Shell building equipment includes a variety of tools and machines, such as dipping tanks, slurry mixers, and drying ovens. The wax patterns are dipped into a ceramic slurry and then coated with a refractory material. This process is repeated multiple times to build a thick and strong ceramic shell around the patterns.

- Dewaxing Equipment: Dewaxing is a critical step in investment casting, where the wax is removed from the ceramic shell to create the mold cavity. Dewaxing equipment includes autoclaves or steam chambers, where the ceramic shells are placed and heated to melt and vaporize the wax. The wax is collected, condensed, and reused, making the process more sustainable. Dewaxing equipment ensures efficient and complete removal of the wax, leaving a clean and precise mold cavity.

- Melting Furnaces: Melting furnaces are used to melt the metal alloy that will be poured into the ceramic shell. These furnaces are designed to reach and maintain high temperatures required to melt various types of metals, such as stainless steel, aluminum, bronze, or titanium. Melting furnaces are equipped with precise temperature controls, crucibles to hold the molten metal, and mechanisms to pour the molten metal into the mold.

- Casting Machines: Casting machines are used to pour the molten metal into the ceramic shell to create the final component. These machines ensure controlled and precise pouring of the metal to minimize defects and achieve consistent results. Different types of casting machines are available, including gravity casting machines, vacuum casting machines, and centrifugal casting machines. The choice of casting machine depends on the specific requirements of the part and the metal being cast.

- Post-Casting Equipment: After the metal has solidified and the ceramic shell is broken away, post-casting equipment is used to remove any remaining shell material and to clean and finish the cast components. This may include sandblasting equipment, grinding and polishing machines, and various inspection tools to ensure the final parts meet the required specifications.

Benefits of Investment Casting Equipment:

- Precision and Complexity: Investment casting equipment enables the production of highly precise and intricate components. The wax patterns and ceramic shells allow for the replication of complex geometries and fine details, which may be challenging or impossible with other casting methods. This precision and complexity make investment casting ideal for industries such as aerospace,automotive, and medical, where intricate and high-quality components are required.

- Versatility: Investment casting equipment offers versatility in terms of the materials that can be used. It supports a wide range of metals and alloys, including stainless steel, aluminum, bronze, titanium, and superalloys. This versatility allows manufacturers to choose the most suitable material for their specific application, considering factors such as strength, corrosion resistance, and thermal properties.

- Dimensional Accuracy: Investment casting equipment ensures excellent dimensional accuracy in the final components. The use of precise wax patterns and ceramic shells, along with controlled melting and pouring processes, minimizes dimensional variations. This accuracy eliminates or reduces the need for extensive post-casting machining, resulting in cost savings and faster production times.

- Surface Finish: The investment casting process, facilitated by the equipment, produces components with excellent surface finishes. The ceramic shell molds provide a smooth surface texture, reducing the need for additional surface treatments or finishing processes. This is particularly advantageous for components that require a high-quality surface appearance, such as jewelry, decorative pieces, or parts for high-end machinery.

- Design Flexibility: Investment casting equipment allows for design flexibility, enabling the production of intricate and complex shapes. It supports the creation of parts with thin walls, undercuts, internal features, and complex geometries that may be challenging to achieve with other manufacturing methods. This design flexibility opens up possibilities for innovative product designs and improved functionality.

- Cost-Effectiveness: While investment casting equipment may require upfront investment, it can offer long-term cost savings in various ways. The precision and accuracy of the process minimize material waste, reducing overall production costs. Additionally, the ability to produce complex components in a single casting eliminates the need for multiple machining operations and assembly, saving time and labor costs.

- Quality Control: Investment casting equipment allows for consistent and repeatable production, contributing to quality control. The use of advanced technologies and process controls ensures that each casting meets the required specifications and quality standards. This level of control helps manufacturers maintain high-quality standards and meet customer expectations.

In conclusion, investment casting equipment is vital for the production of high-quality, complex, and precise components in various industries. The equipment, including wax injection machines, shell building equipment, melting furnaces, casting machines, and post-casting tools, enables the entire investment casting process from pattern creation to the final component. With its benefits of precision, versatility, dimensional accuracy, surface finish, design flexibility, cost-effectiveness, and quality control, investment casting equipment provides manufacturers with the capability to produce intricate and reliable parts for a wide range of applications. By leveraging the capabilities of investment casting equipment, manufacturers can achieve superior results, optimize production processes, and meet the demands of modern industries.