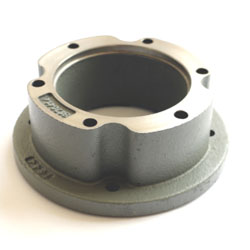

Iron Castings

Leehwa Casting manufactures investment castings and iron castings in Dongying City, Shandong Province, China. We have our own factory of iron castings. Leehwa Casting provides the high quality and competitive price on sand castings for you. Contact us now for a quotation.

- 20+ years Castings manufacturing experience

- Up to 5 years of warranty

- Full support on your customised requirement

Quick Details : iron Castings.

China Customized Precoated Sand Casting Cast Iron Parts Ductile Iron Grey Iron

-Sand Casting;

-Acceptable Materials:

GGG50,GGG30,

ASTMA48 class25B,

42CrMo4, C22

ductile iron 65-45-12,

AlCuMgpbF34,

EN-JIS-500-7 EN1563 ,

EN10293-GE300

HT200,

DIN17205-GS-25CrMo4

Leehwa Casting Co., Ltd., a professional manufacturer of iron casting parts for auto and industrial machinery.

Main products: gray iron casting, ductile casting, steel castings, sand castings.

Main Equipment:

Disa 131 Sand Molding Line,

Inductothermo Furnaces & Pouring System,

Hyundai Machining System.

Advantages:

1) Quality guaranteed by advanced equipment.

2) Supported by ISO9001, 14001 & IATF16949.

3) Experienced team.

4) Reliable R&D engineers.

Quick Details:

Place of Origin: Shandong, China

Brand Name: Leehwa Casting

Model Number: 025

Product name:

Hot Sale Foundry Cast Iron Casting Base Cast Iron Parts

Name:

Iron casting part

Packing: Carton

Service: OEM\ODM

Color: Customized Color

Packaging & Delivery

Packaging Details

In wooden casing or steel case.

Optional inner package: polybag or woven bag.

Port Tianjin Xingang

Sand Casting: A Versatile and Widely Used Casting Process

Sand casting is one of the oldest and most widely used casting processes in the manufacturing industry.

It involves creating molds made of sand, into which molten metal is poured to create various complex and intricate shapes.

This versatile casting method is utilized in a wide range of industries, including automotive, aerospace, construction, and more. In this article, we will explore the basics of sand casting and its advantages.

The Process:

Sand casting begins with the creation of a pattern, typically made of wood or metal, which represents the shape of the final desired product.

The pattern is used to make a mold by packing specially formulated sand around it.

The mold is then carefully separated into two halves, known as the cope and drag.

These halves are prepared by adding additional features such as gates, runners, and risers to facilitate the flow of molten metal and ensure proper filling of the mold.

Once the mold is ready, it is securely closed and molten metal is poured into the cavity created by the pattern.

The metal is allowed to cool and solidify, after which the mold is opened, and the casting is removed.

The casting is then cleaned, finished, and undergoes any necessary post-processing operations such as heat treatment, machining, or surface treatment to achieve the desired specifications.

Advantages of Sand Casting:

Versatility: Sand casting is highly versatile, allowing the production of intricate and complex shapes with various sizes and weights. It can accommodate both small and large-scale production runs, making it suitable for a wide range of applications.

Cost-Effective: Compared to other casting methods, sand casting is relatively inexpensive. The materials used, such as sand and pattern materials, are affordable, and the process requires minimal equipment investment, resulting in lower production costs.

Wide Material Selection: Sand casting can accommodate a wide range of metals and alloys, including aluminum, iron, steel, brass, and bronze. This flexibility in material selection allows manufacturers to choose the most suitable material for the specific application, considering factors such as strength, durability, and corrosion resistance.

Design Flexibility: Sand casting offers design flexibility, as complex shapes and intricate details can be achieved without the limitations imposed by other casting processes. It allows for the creation of undercuts, thin walls, and hollow sections that may be challenging to produce using alternative methods.

Excellent Surface Finish: With proper mold preparation and post-casting treatments, sand castings can achieve a smooth surface finish. This makes them suitable for applications where aesthetics and surface quality are important, such as decorative components or parts requiring minimal post-casting machining.

Tooling Modifications: One of the advantages of sand casting is the ease of modifying the pattern or mold during the production process.

If design changes are required, adjustments can be made to the pattern quickly and at a relatively low cost, allowing for agile manufacturing and adaptability.

Applications of Sand Casting:

Sand casting finds applications in a wide range of industries, including automotive, aerospace, agriculture, construction, and more.

It is commonly used to produce components such as engine blocks, cylinder heads, transmission cases, pump housings, gears, and various structural parts.

The ability to create complex shapes and the cost-effectiveness of sand casting make it a popular choice for both small-scale and large-scale production of metal components.

In conclusion, sand casting is a versatile and widely used casting process that offers numerous advantages for manufacturers.

Its versatility, cost-effectiveness, wide material selection, design flexibility, excellent surface finish, and ease of tooling modifications make it an attractive option for producing a variety of components across different industries.

As technology continues to advance, sand casting techniques and materials are evolving, further enhancing its capabilities and expanding its applications in the manufacturing world.