steel castings

Leehwa Casting manufactures sand castings and iron castings in Dongying City, Shandong Province, China. We have our own factory of iron castings. Leehwa Casting provide the high quality and competitive price on sand castings for you. Contact us now for quotation.

- 20+ years Castings manufacturing experience

- Up to 5 years of warranty

- Full support on your customised requirement

Quick Details : iron Castings.

China Customized Precoated Sand Casting Cast Iron Parts Ductile Iron Grey Iron

-Sand Casting;

-Acceptable Materials:

GGG50,GGG30,

ASTMA48 class25B,

42CrMo4, C22

ductile iron 65-45-12,

AlCuMgpbF34,

EN-JIS-500-7 EN1563 ,

EN10293-GE300

HT200,

DIN17205-GS-25CrMo4

Leehwa Casting Co., Ltd., a professional manufacturer of iron casting parts for auto and industrial machinery.

Main products: gray iron casting, ductile casting, steel castings, sand castings.

Main Equipment:

Disa 131 Sand Molding Line,

Inductothermo Furnaces & Pouring System,

Hyundai Machining System.

Advantages:

1) Quality guaranteed by advanced equipment.

2) Supported by ISO9001, 14001 & IATF16949.

3) Experienced team.

4) Reliable R&D engineers.

Quick Details:

Place of Origin: Shandong, China

Brand Name: Leehwa Casting

Model Number: 025

Product name:

Hot Sale Foundry Cast Iron Casting Base Cast Iron Parts

Name:

Iron casting part

Packing: Carton

Service: OEM\ODM

Color: Customized Color

Packaging & Delivery

Packaging Details

In wooden casing or steel case.

Optional inner package: polybag or woven bag.

Port Tianjin Xingang

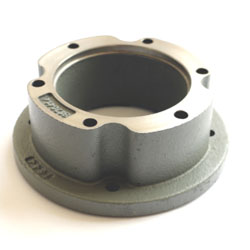

Picture Example:

Steel Castings: Versatile and Reliable Components for Diverse Applications

Steel castings are widely recognized for their versatility, durability, and strength. They play a crucial role in numerous industries, including automotive, construction, oil and gas, aerospace, and more. In this article, we will explore the characteristics, manufacturing process, and applications of steel castings.

Characteristics of Steel Castings:

Steel castings offer several key characteristics that make them highly desirable in various applications:

Strength and Durability: Steel is renowned for its exceptional strength and durability, making steel castings capable of withstanding heavy loads, high temperatures, and harsh environments. They exhibit excellent mechanical properties, including toughness, hardness, and impact resistance.

Versatility: Steel castings can be produced in a wide range of shapes, sizes, and complexities. This versatility allows for the manufacturing of components with intricate geometries, thin walls, and precise details, meeting the specific requirements of diverse industries.

Corrosion Resistance: Many steel alloys possess inherent corrosion resistance, making steel castings suitable for applications exposed to corrosive environments, such as marine equipment, chemical processing, and infrastructure exposed to harsh weather conditions.

Weldability and Machinability: Steel castings offer excellent weldability, allowing for the joining of components through various welding techniques. Additionally, they are easily machinable, facilitating the production of finished components with tight tolerances.

Manufacturing Process of Steel Castings:

The manufacturing process of steel castings involves several key steps:

Pattern Making: The process begins with the creation of a pattern, typically made of wood, plastic, or metal, which replicates the shape of the desired component. The pattern is used to create a mold cavity.

Molding: The pattern is placed in a molding material, such as sand, to form the mold. The mold is divided into two halves, the cope and the drag, and additional features like gates, runners, and risers are added to facilitate the pouring of molten metal.

Melting and Pouring: Steel is melted in a furnace at high temperatures, typically using electric arc furnaces or induction furnaces. Once the steel reaches the desired temperature and composition, it is poured into the prepared mold cavity through the gating system.

Solidification and Cooling: The molten steel solidifies and cools inside the mold, taking the shape of the pattern. Proper cooling rates are crucial to achieving the desired microstructure and mechanical properties of the steel casting.

Shakeout and Cleaning: After the steel has solidified, the mold is broken or shaken off, and the casting is removed. The casting undergoes cleaning processes, such as shot blasting or machining, to remove any residual mold material and achieve the required surface finish.

Applications of Steel Castings:

Steel castings find extensive applications across various industries due to their exceptional properties:

Automotive: Steel castings are used in the automotive industry to manufacture engine components, transmission parts, suspension systems, and brake components.

Their strength, durability, and ability to withstand high temperatures make them ideal for demanding automotive applications.

Construction and Infrastructure: Steel castings play a vital role in the construction industry, used in applications such as structural components, bridges, building frames, and heavy machinery.

They provide the required strength and stability to withstand heavy loads and harsh environmental conditions.

Oil and Gas: In the oil and gas industry, steel castings are used in drilling equipment, valves, pumps, and pipeline components.

Their resistance to corrosion, high pressure, and extreme temperatures make them suitable for challenging oil and gas exploration and production environments.

Aerospace: Steel castings are utilized in the aerospace industry for manufacturing critical components such as turbine blades, engine casings, landing gear parts and structural components of aircraft.

The high strength-to-weight ratio of steel castings makes them ideal for aerospace applications, where performance, reliability, and safety are paramount.

Machinery and Equipment: Steel castings are widely used in the production of machinery and equipment, including agricultural machinery, mining equipment, material handling systems, and industrial machinery.

Their durability and resistance to wear and impact make them suitable for heavy-duty applications.

Energy and Power Generation: Steel castings play a significant role in the energy and power generation industry, where they are used in components such as turbine parts, generator housings, and valve bodies.

The ability of steel castings to withstand high temperatures and pressure conditions is crucial for efficient power generation.

Railways: Steel castings are utilized in the railway industry for the manufacturing of locomotive components, railcar bogies, and infrastructure elements. Their strength and reliability contribute to the safe and efficient operation of railway systems.

Conclusion:

Steel castings are versatile components that offer exceptional strength, durability, and reliability for a wide range of applications.

Their characteristics, including high strength, corrosion resistance, weldability, and machinability, make them a preferred choice in industries such as automotive, construction, oil and gas, aerospace, and more.

The precise manufacturing process ensures the production of complex and intricate components that meet stringent specifications and requirements.

With their remarkable properties, steel castings contribute to the development of robust and efficient products across diverse sectors, playing a vital role in advancing industries and driving innovation.