Stainless Steel Investment Casting

Leehwa Casting manufactures investment castings and iron castings in Dongying City, Shandong Province, China. We have our own factory of iron castings.Leehwa Casting provide the high quality and competitive price on sand castings for you. Contact us now for a quotation.

- 20+ years Castings manufacturing experience

- Up to 5 years of warranty

- Full support on your customised requirement

- Affordable Tooling: Tooling is the basic step to starting the stainless steel casting process. Although the machining accuracy and material of tooling play an important role in the final casting quality, the tooling of stainless steel is relatively affordable compared with other forming processes.

- Flexible design: Investment casting can cast out stainless steel products in different sizes and weights, so the design of cast stainless steel parts is very flexible. Stainless steel casting allows parts with a minimum 3mm thickness and weights ranging from 0.05kgs-80kgs. Besides, stainless steel castings with complex structures are also castable.

- Close Tolerance: The dimensional accuracy of stainless steel investment casting can meet ISO 8062 CT5-CT6 level. Such close tolerance can ensure stainless steel castings with less or no machining.

- Good Surface: Even after shot blasting, the surface of stainless steel castings is very smooth and looks bright. And people will never worry about stainless steel castings will get rust with time flys.

- High Production Efficiency: Stainless steel casting is a fast and repeatable process, so the production efficiency is very high, and no matter it is a large or small volume, it can all meet.

Quick Details:

Place of Origin: Shandong, China

Brand Name: Leehwa Casting

Model Number: 025

Product name:

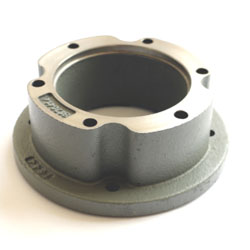

Hot Sale Foundry Cast Iron Casting Base Cast Iron Parts

Name:

Iron casting part

Packing: Carton

Service: OEM\ODM

Color: Customized Color

Packaging & Delivery

Packaging Details

In wooden casing or steel case.

Optional inner package: polybag or woven bag.

Port Tianjin Xingang

Stainless Steel Investment Casting: A Precise and Versatile Manufacturing Process

Stainless steel investment casting, also known as precision casting or lost-wax casting, is a widely utilized manufacturing process for producing high-quality stainless steel components with intricate designs and precise dimensions.

This article explores the characteristics, advantages, and applications of stainless steel investment casting.

Characteristics of Stainless Steel Investment Casting:

Stainless steel investment casting offers several key characteristics that make it highly desirable in various industries:

Corrosion Resistance: Stainless steel is renowned for its excellent corrosion resistance properties.

It can withstand harsh environments, high temperatures, and exposure to chemicals, making it suitable for applications in industries such as marine, oil and gas, and food processing.

Design Flexibility: Investment casting allows for the creation of complex and intricate designs with fine details that are challenging to achieve through other manufacturing processes.

This versatility in design enables the production of components with precise dimensions and intricate features.

Superior Surface Finish: Stainless steel investment castings exhibit a smooth and high-quality surface finish.

This eliminates the need for extensive post-casting machining or surface treatment, saving both time and cost in the production process.

Material Variety: Stainless steel investment casting supports a wide range of stainless steel alloys, offering manufacturers the flexibility to choose the most suitable material for their specific application.

This allows for tailoring the component’s properties, such as strength, hardness, and corrosion resistance, to meet the desired requirements.

Advantages of Stainless Steel Investment Casting:

Precision and Accuracy: Stainless steel investment casting ensures high precision and accuracy in the production of components.

The process allows for the replication of intricate details and complex geometries, resulting in components with tight tolerances and precise dimensions.

Versatility: Stainless steel investment casting can accommodate a broad range of component sizes, from small intricate parts to large and complex structures.

This versatility makes it suitable for various industries, including automotive, aerospace, medical, and energy.

Cost-Effective: While stainless steel investment casting may require initial investment in tooling and equipment, it offers long-term cost advantages.

The process minimizes material waste, reduces the need for extensive machining, and allows for the production of near-net-shape components, resulting in cost savings and improved efficiency.

Enhanced Mechanical Properties: Stainless steel investment castings exhibit excellent mechanical properties, including high strength, hardness, and impact resistance.

This makes them suitable for applications requiring structural integrity and durability.

Applications of Stainless Steel Investment Casting:

Stainless steel investment casting finds extensive applications across numerous industries:

Aerospace: The aerospace industry relies on stainless steel investment castings for producing components such as turbine blades, engine parts, structural components, and fuel system components.

The high precision and strength of investment castings contribute to the performance and reliability of aerospace systems.

Automotive: In the automotive industry, stainless steel investment castings are used for manufacturing engine components, exhaust systems, suspension parts, and braking components.

The corrosion resistance and strength of stainless steel make it ideal for withstanding demanding automotive environments.

Medical and Dental: Stainless steel investment castings are employed in the medical and dental fields for the production of surgical instruments, orthopedic implants, dental prosthetics, and medical equipment.

The biocompatibility of stainless steel ensures its suitability for medical applications.

Energy and Power Generation: Stainless steel investment castings are utilized in the energy and power generation sector for manufacturing turbine components, valve bodies, and heat exchangers.

The corrosion resistance and heat resistance of stainless steel are crucial for efficient power generation.

Conclusion:

Stainless steel investment casting is a precise and versatile manufacturing process that enables the production of high-quality stainless steel components with complex geometries and superior surface finish.

The corrosion resistance, design flexibility, and material variety of stainless steel investment castings make them an excellent choice for industries such as aerospace, automotive, medical, and energy.

The advantages of precision and accuracy, versatility, cost-effectiveness, and enhanced mechanical properties further highlight the benefits of stainless steel investment casting.

By leveraging the capabilities of stainless steel investment casting, manufacturers can achieve components with exceptional quality, dimensional accuracy, and intricate designs.

The process allows for the production of near-net-shape components, minimizing the need for secondary machining operations and reducing material waste.

This not only streamlines the manufacturing process but also leads to cost savings and improved production efficiency.

In the aerospace industry, stainless steel investment castings are critical for the production of components subjected to extreme conditions, such as turbine blades and engine parts.

The ability to create complex geometries and maintain tight tolerances ensures optimal performance and reliability in aircraft systems.

Within the automotive sector, stainless steel investment castings find applications in engine components, exhaust systems, and braking components.

The corrosion resistance of stainless steel makes it well-suited for withstanding harsh environmental conditions and prolonging the lifespan of automotive parts.

In the medical and dental fields, stainless steel investment castings are integral to the production of surgical instruments, orthopedic implants, and dental prosthetics.

The biocompatibility of stainless steel ensures its compatibility with the human body, making it a reliable and safe material for medical applications.

Furthermore, the energy and power generation industry heavily relies on stainless steel investment castings for turbine components, valve bodies, and heat exchangers.

The ability of stainless steel to withstand high temperatures, corrosion, and pressure is vital for efficient power generation and the longevity of equipment in this sector.

In conclusion, stainless steel investment casting is a versatile and precise manufacturing process that offers numerous advantages for producing high-quality components.

Its ability to create intricate designs, achieve tight tolerances, and provide corrosion resistance makes it invaluable across various industries.

Whether in aerospace, automotive, medical, or energy applications, stainless steel investment castings contribute to the production of reliable, durable, and efficient components.

By harnessing the capabilities of stainless steel investment casting, manufacturers can meet the stringent requirements of their industries and deliver products of exceptional quality and performance.